Mining geomechanics

GMT integrates field data, rock mass expertise and cutting-edge numerical modelling to manage geotechnical risks in open pit and underground operations, ensuring safe, stable and efficient mining.

Orebody knowledge

Geotechnical investigation and characterization

Geotechnical investigation programs are designed and executed to collect high-quality data on the rock mass. Work includes geological and structural mapping of outcrops, pit walls and underground openings, oriented core drilling and detailed geotechnical logging. Rock mass properties are defined through laboratory and in situ testing, supported by classification systems such as RMR, Q and GSI. The outcome is a robust geotechnical database and model that form the foundation of all designs. Strong emphasis is placed on data quality, database integrity and QA/QC to ensure confidence in every input.

Geological and structural mapping. Detailed mapping of pit walls, outcrops and underground openings to define structural controls and domains.

Geotechnical logging and sampling. High-quality core logging, oriented core analysis and testing to establish reliable rock mass properties.

Rock mass and structural modelling. Defining the key domains that control ground behaviour and guide engineering design.

Rock mass response to mining

Numerical modelling

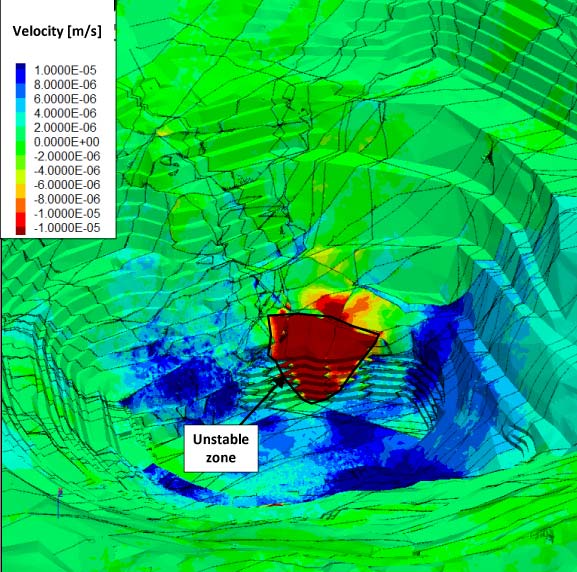

Numerical modelling and design analysis support the evaluation of ground response across open pit and underground mines. Mine-scale simulations incorporate geological, structural and excavation inputs to assess stress, deformation and stability under multiple design scenarios. These analyses help refine sequencing, layout options and excavation geometries, ensuring decisions are grounded in realistic behaviour. Close collaboration with site teams ensures that assumptions are transparent, outputs are clearly interpreted and the results inform practical, operationally reliable designs.

Behaviour simulation. Assessment of ground response under varying conditions to guide design choices and operational planning.

Layout optimisation. Comparison of alternative geometries and sequences to identify stable, efficient excavation strategies.

Design integration. Translation of modelling outcomes into clear engineering recommendations aligned with operational requirement

Rock mechanics

Underground geomechanics

Our underground rock mechanics capability covers all major mining methods, including block caving, sub-level caving, sub-level stoping, room and pillar, and cut and fill or bench and fill. Our strength in mass mining is particularly well established, with recognised expertise in block and sub-level caving design, evaluation, and operational support. Our services include mining method evaluations, stope and pillar stability assessments, sequencing optimisation, and the analysis of mine layouts and critical infrastructure. We design static and dynamic ground support systems, analyse fragmentation and caving behaviour, forecast subsidence, manage mine-induced seismicity and rockburst hazards, and develop instrumentation and monitoring programs that support safe and efficient operations.

Mining method and excavation stability assessment. Evaluating method selection, stope and pillar stability, and sequencing to ensure safe and efficient extraction.

Ground support and seismic management. Designing static and dynamic support systems and managing mine-induced seismicity and rockburst hazards.

Cave mining analysis. Assessing fragmentation, caving propagation and subsidence, and evaluating stability across the footprint and critical infrastructure.

Geotechnical design

Open pit slope engineering

GMT provides a full suite of open pit geotechnical services focused on understanding and managing the mechanisms that control slope performance. Our work spans bench, inter-ramp and overall slope scales, combining kinematic assessments, limit-equilibrium analysis and advanced numerical modelling to evaluate rock mass strength, deformability and potential failure modes. This approach allows us to define slope geometries that deliver an optimal balance between value and geotechnical risk, ensuring designs remain both efficient and defensible. We undertake back-analyses of instabilities to refine geotechnical models and strengthen future designs. Our team also develops monitoring strategies and trigger-action response plans as part of a comprehensive Ground Control Management Plan, supporting reliable decision-making throughout the life of the pit.

Risk-aligned slope definition. Assessment of mechanisms, behaviours and data confidence to support stable, value-optimised designs.

Capability development. Establishment of frameworks and processes that strengthen long-term geotechnical decision making within client teams.

Life-of-mine integration. Connection of design, monitoring and operational controls to maintain slope performance throughout the pit life.

Excavation support systems

Ground support

Designing effective ground support systems is a core competency of our geomechanics team. We specify support systems for both static and dynamic conditions, tailored to ground conditions and excavation demands. Our work includes benchmarking support practices across comparable operations to align designs with proven performance and identify improvement opportunities. We have also pioneered deformation-based ground support design approaches in high-stress mines to improve performance and reduce support costs.

Support strategy definition. Selection and specification of static and dynamic systems matched to ground conditions and excavation demands.

Benchmarking and performance alignment. Comparison of support practices across similar operations to validate designs and identify improvement opportunities.

Dynamic ground response. Application of deformation-based design principles to improve support performance in high-stress environments.

Geotechnical governance

Geotechnical risk management and audit

GMT supports clients in developing, reviewing and strengthening their ground control management plans and geotechnical risk management systems. We conduct independent audits and peer reviews for studies and operating mines, benchmarking practices against industry standards to evaluate the reliability of data, design assumptions and monitoring systems. Gaps and vulnerabilities are clearly identified, with practical recommendations provided to enhance safety, compliance and operational consistency. Our team facilitates structured risk assessments, including geohazard bow-tie reviews, and delivers ground-awareness training to build capability across site teams. For companies aiming to improve their geotechnical governance, we assist in developing corporate standards, design charters and data sufficiency criteria, supporting a consistent and defensible level of geotechnical rigour across all operations

Independent review. Evaluation of design inputs, controls and monitoring systems through objective audits and peer reviews.

Risk assesment. Facilitation of structured risk assessments to identify hazards, critical controls and enable decision pathways across the mine lifecycle.

Corporate geotechnical strengthening. Development of standards, design charters and data requirements to support consistent governance.

Ready to build with confidence?

Talk to our experts.